About Us

Enertechnos is a pioneering clean tech company dedicated to delivering decarbonisation.

Who We Are

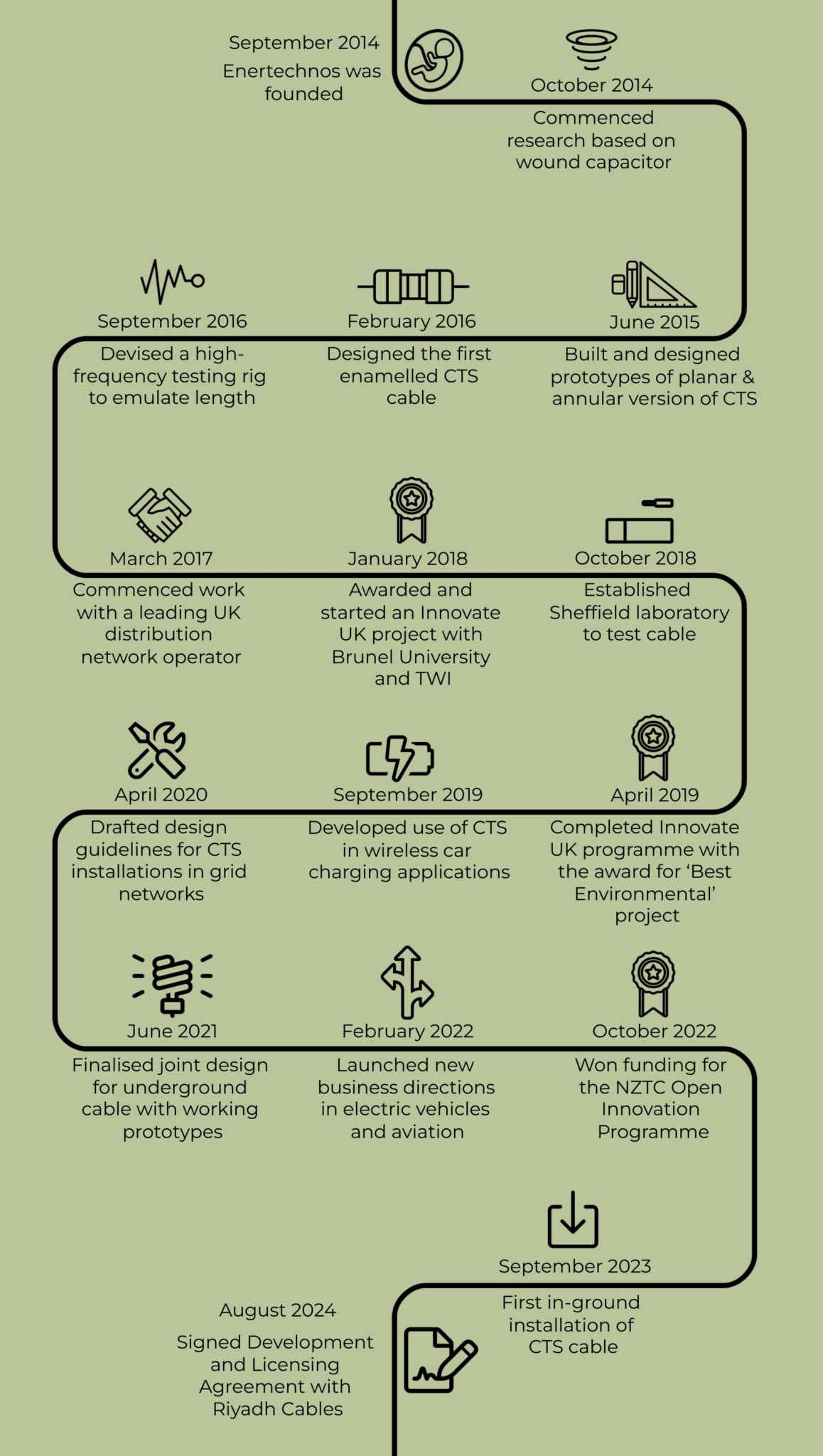

Enertechnos was founded with a singular purpose: to provide a solution to help to deliver decarbonisation.

Soon enough, it became clear that electricity is a key player when it comes to reducing carbon emissions.

What We Do

In our journey to become clean tech pioneers, we invented – and patented – a concept called ‘Capacitive Transfer System’ (CTS).

CTS reduces power delivery loss and, more importantly, can deliver more power through the same conductor mass or operate at higher frequencies than conventional legacy cables.

Who we are

Enertechnos was founded with one vision in mind: to provide a solution to deliver decarbonisation. Soon enough, it became clear that whenever the question involves ‘decarbonisation’, the answer always involves ‘electricity’.

What we do

We invented and patented a concept called ‘Capacitive Transfer System’ (CTS), which reduces power delivery and, more importantly, can deliver more power through the same mass of conductor or operate at high frequencies than conventional legacy cables.

Our CTS cables can be easily manufactured in existing factories on standard cable-making machinery.

While developing the CTS concept, a large part of the engineering effort in recent years has been to adapt CTS to multiple applications while designing cables that can be made in any existing cable factories. Enertechnos’ strategy is not to be a manufacturer but to licence its technology to cable and hardware manufacturers worldwide.

Market Opportunity

In 2020, the market globally for cable and wire was circa $90 billion and projected overall grid investments to transition to net zero by 2050 was around $14 trillion. The breakdown of this $14 trillion was comprised of sustainment capital in replacing assets at end of life (48%), grid reinforcement (38%) and new connections (21%).

At the same time, there was a focus on providing EV charging infrastructure to convert billions of existing fossil fuel-driven vehicles to electric. This came in tandem with decarbonising the aviation sector and legacy fossil fuel producers.

Market Opportunity

In 2020 the market globally for cable and wire was circa $90 billion and projected overall grid investments to transition to net zero by 2050 is around $14 trillion where 48% of that value is sustainment capital in replacing assets at end of life, 38% is for grid reinforcement and 21% is for new connections. At the same time we have to provide EV charging infrastructure to convert billions of existing fossil fuel driven vehicles to electric, decarbonise aviation with several thousands of airports and even legacy fossil fuel producers.

Want to get in touch?

We’re proud to be at the forefront of the clean tech industry and always looking for opportunities for our technology to be used across countries and industries.

Feel free to get in touch by clicking the link below.

Want to get in Touch?

We’re proud to be at the forefront of the clean tech industry and are always looking for application opportunities for our technology.

Get in touch by clicking the link below.